Efficient particulate collection is central to modern industrial air pollution control, making the baghouse a familiar engineering solution across thousands of factories, mines, and processing plants. However, understanding and maintaining baghouse performance requires more than mechanical know-how: it demands continuous, reliable quantitative feedback on system health. The Magnahelic differential pressure gauge stands forefront as the industry’s most widely specified tool for this task. The following guide reviews—at advanced technical depth—how and why this instrument is used, what it reveals about filter bags and system dynamics, and how its data translate into operational decisions, cost control, and compliance.

Baghouses utilize rows of fabric filter bags to separate dust or particulate matter from high-volume process air. Dirty gas enters the “dirty-air” plenum, passes through the filter bags, and exits as cleaned air. The filter bags capture particles via mechanical sieving, inertial impaction, and electrostatic attraction, all while allowing filtered gas to pass. Over time, dust accumulates on and within the bag fabric, forming a dust cake that enhances filtration at first but ultimately restricts airflow and raises system resistance.

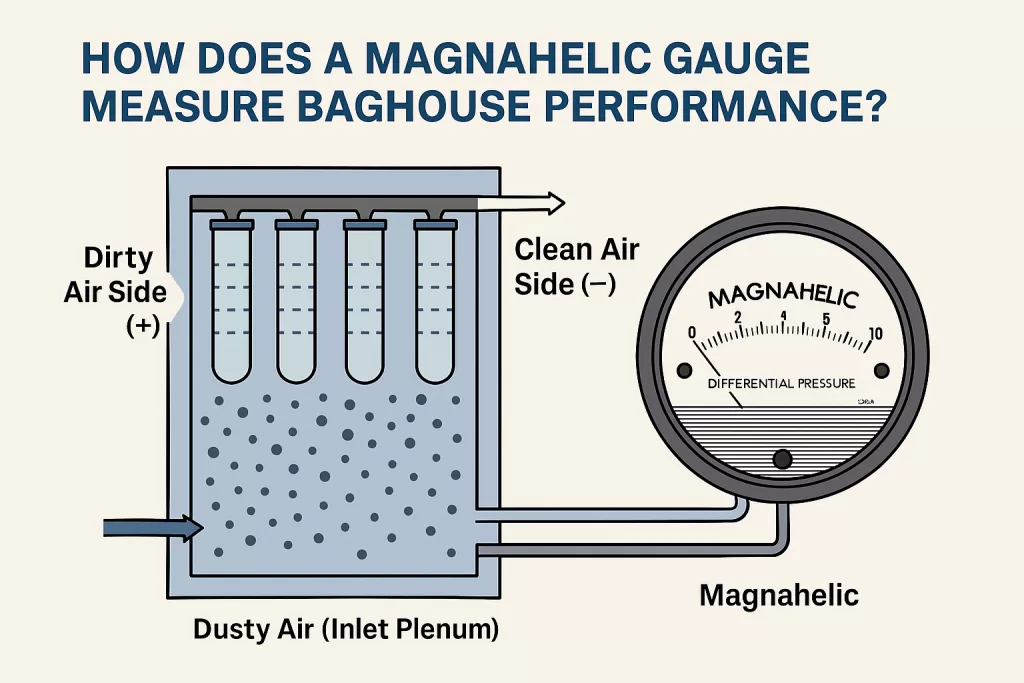

The performance and health of this filtration process cannot be judged by visual inspection alone. Operators require real-time quantifiable measures to diagnose filter condition, monitor system integrity, ensure regulatory compliance, and forecast maintenance needs. Among several possible metrics, the differential pressure (“dP” or “Delta-P”) across the filter media is universally recognized as the primary performance indicator. The Magnahelic gauge is engineered to deliver this measurement with simplicity, ruggedness, and repeatable accuracy.

The baghouse’s differential pressure is defined as the pressure drop from the dirty-air side to the clean-air side of the filter array:ΔP=Pdirty−PcleanΔP=Pdirty−Pclean

Practically, as dust accumulates and bags blind, resistance to airflow increases—meaning the fan must work harder to move gas through the same number of filters, and the dP rises. In contrast, clean (or leaking) filters show a lower resistance and dP.

The Magnahelic gauge utilizes two pressure ports: one is installed on the dirty side (before the bags), and one on the clean side (after the bags). Inside the gauge, a spring-loaded diaphragm translates the pressure differential into a mechanical needle reading on a calibrated scale (typically 0–10 or 0–20 inches of water gauge, “in. w.g.”). The reading is continuous and analog, immediately visible to operators and maintenance staff.

Pulse-jet baghouses periodically clean bags by briefly injecting compressed air (“pulses”) into bag interiors. Watching the Magnahelic gauge reveals this cycle in real time:

Magnahelic readings are central to diagnostic procedures. Typical anomalies seen on the gauge and their associated root causes:

While the Magnahelic gauge is robust, several caveats apply:

Regular calibration and cross-checking with alternative sensors can ensure continued accuracy.

In summary, the Magnahelic gauge provides the cornerstone measurement (differential pressure) required to maintain, troubleshoot, and optimize baghouse performance. Its application supports predictive maintenance, regulatory compliance, and operational safety. For manufacturers, integrators, or operators of dust filter bags and baghouse systems, expertise in differential pressure monitoring—and best practices for instrument installation, trend analysis, and maintenance—is vital for maximizing filter life, ensuring process efficiency, and protecting environmental and worker health.

Introduction Efficient particulate collection is central to modern industrial air pollution control, making the baghouse a familia

By Omela Filtration — Industrial Filtration Experts 1. Industry Background and the Real Problem In pulse-jet dust collector syst

By Omela Filtration – Industrial Filtration Experts Industry Background and Challenges Most industrial dust collector systems re