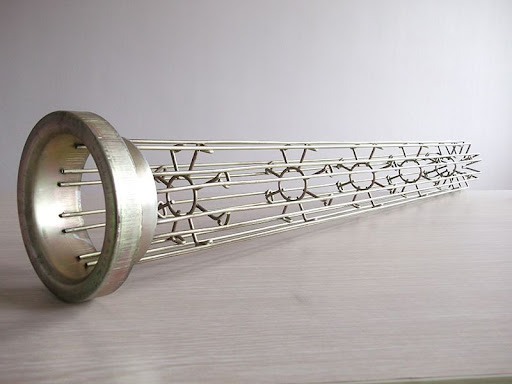

Pleated filter bag cages are specifically engineered to support pleated (star-shaped or cylindrical) filter bags, offering a high-efficiency solution for modern dust collection systems. Unlike traditional round bag cages, pleated cages provide increased filtration surface area in the same—or even reduced—installation space, allowing for higher air volume throughput, lower differential pressure, and compact system design.

The pleated structure increases the surface area of the filter bag by 1.5x to 2.5x compared to traditional cylindrical bags, which translates into:

Pleated filter bag cages are ideal for high-performance industrial dust collection where space optimization and airflow efficiency are critical:

They are especially favored in retrofit applications where increasing capacity without modifying the entire dust collector is necessary.

| Feature | Advantage |

|---|---|

| Increased Filter Area | 1.5–2.5 times more area than standard cylindrical bags |

| Space-Efficient Design | Reduces collector size while maintaining performance |

| Lower Differential Pressure | Improves airflow, reduces fan load, and saves energy |

| Improved Bag Stability | Provides uniform support to pleated structure and reduces bag vibration |

| Retrofit-Friendly | Ideal for upgrading existing dust collection units without major redesign |

| Item | Specification |

|---|---|

| Material | Carbon Steel, Stainless Steel (304/316), with optional coating |

| Surface Finish | Plain / Galvanized / Epoxy Coated / Silicone Coated |

| Structure | Star-shaped / Pleated cylindrical cage |

| Pleat Support Ribs | Radial or longitudinal for even pleat support |

| Wire Diameter | 3.0–5.0 mm |

| Cage Length | 500–2000 mm (customizable) |

| Top Cap Design | Snap band / Flange / Venturi |

| Operating Temperature | Up to 260°C (depending on material and coating) |

| Bag Diameter Supported | 120mm / 150mm / 160mm / Custom sizes |

| Corrosion Resistance | Varies with surface treatment (epoxy, silicone, SS) |

Pleated filter bag cages are an intelligent upgrade for modern filtration systems. Whether you’re designing a new dust collector or retrofitting an old one, this cage type offers superior performance in a compact package.

For industries that demand high filtration efficiency, limited space usage, and cost-effective upgrades, Omela’s Pleated Filter Bag Cages are a smart and reliable choice.