Pre-Project Technical Support

- Airstream assessment: airflow, temperature, humidity

- Dust assessment: inlet loading, particle size, particle shape

- Define collection efficiency & emission compliance targets

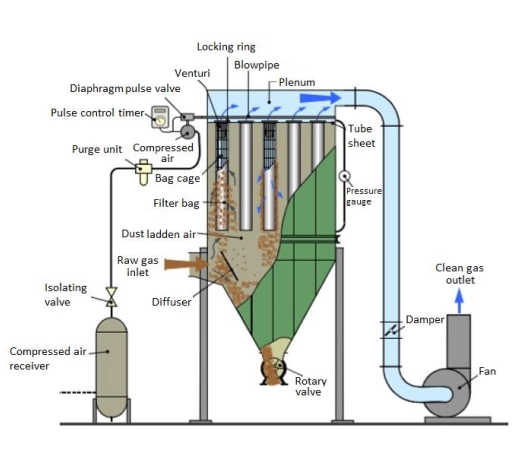

A Pulse Jet Baghouse Dust Collector is a high-efficiency particulate removal system designed to capture fine dust from industrial exhaust gas streams using fabric filter bags and compressed-air pulse cleaning. It is widely applied in industries requiring stable emission control, continuous operation, and compliance with environmental regulations, such as cement production, steel plants, power generation, chemical processing, and waste incineration.

Compared with mechanical or wet dust collectors, pulse jet baghouses offer higher filtration efficiency (>99%), compact structure, and lower long-term operating cost, making them one of the most widely adopted dust-collection solutions in modern industrial plants.

Dust-laden air enters the baghouse through the inlet duct and flows into the hopper section. Larger and heavier particles drop directly into the hopper by gravity, while finer particles are carried upward and captured on the outer surface of the filter bags.

This process enables high dust removal efficiency with minimal interruption to production.

Optimized filtration efficiency, stable pressure drop, and extended filter bag life directly reduce total operating cost (TCO).

At Omela, our Pulse Jet Baghouse Dust Collector is built as a modular, service-friendly system that integrates dust capture, pulse-jet cleaning, and stable discharge into one compact unit. Dust-laden gas enters through the inlet, heavier particles drop into the hopper, and fine dust is retained on the outer surface of the filter bags. A timed pulse-jet releases compressed air through the blowpipe/venturi to dislodge the dust cake, which falls into the hopper for continuous removal—while clean air exits through the outlet duct to the fan and stack.

Removes over 99% of fine particulate matter, including sub-micron dust.

Pulse jet cleaning maintains consistent ΔP, reducing fan energy consumption.

Automated cleaning minimizes manual intervention and downtime.

Low pressure drop design reduces overall operating cost.

Optimized cleaning frequency and uniform airflow distribution extend bag lifespan.

Easily adapted to different airflow rates, dust characteristics, and site layouts.

| Mode | Filter Bags (Quantity) | Fan (kW) | Quantity of 1" Valves | Dimensions (mm) |

| OM-01MC64 | 64 | 7.5 kW | 8 | 1550*1550*4200 |

| OM-01MC80 | 80 | 7.5 kW | 8 | 1550*2160*4400 |

| OM-01MC140 | 140 | 18.5 kW | 14 | 2560*2160*4400 |

| OM-01MC200 | 200 | 22 kW / 30 kW | 20 | 3580*2160*4800 |

| OM-01MC300 | 300 | 37 kW / 45 kW | 30 | 5400*2160*4800 |

| OM-01MC500 | 500 | 55 kW / 75 kW | 50 | 9500*2160*5000 |

Filtration needs vary from one plant to another, but the goal is the same—stable operation and clean output. Our products are used across different industries with demanding working conditions.

High-efficiency filtration for fine particulates with stable emissions control in continuous operation.

Optimized air-to-cloth ratio and pulse-jet cleaning help maintain stable ΔP and reduce maintenance cost.

Typical savings come from fewer unplanned stoppages, longer bag life, and predictable pressure-drop control.

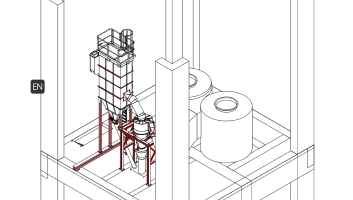

The galvanizing line required a stable dust filtration solution to control fine particulates generated during production. To ensure predictable performance and lower maintenance, Omela delivered a pulse jet baghouse package with differential-pressure controlled cleaning and a fully integrated fan + control cabinet.

The following parameters reflect the final selected engineering solution for this project.

| Application | Hot-dip galvanizing plant dust collection |

| System Type | Pulse-jet baghouse (ΔP-controlled automatic cleaning) |

| Designed Airflow | 18,000 m³/h (selected solution) |

| Equipment Air Volume Range | 18,000–24,000 m³/h |

| Tolerable Temperature | 50°C |

| Bag Material | Polypropylene (PP) |

| Bag Quantity | 160 pcs |

| Bag Size | Ø133 × 2500 mm |

| Total Filter Area | 320 m² |

| Filter Cage / Basket | Stainless steel |

| Pulse Valves | 2" × 20 |

| Explosion-Proof Plate | 4 pcs |

| Power Supply | 400V / 50Hz / 3P |

The pulse cleaning is automatically controlled by differential pressure, which keeps operation stable and reduces manual maintenance during continuous galvanizing production.

45%

Operating Cost Reduction

Optimized airflow design, reduced compressed air consumption, and extended filter bag life lowered total operating costs by approximately 45% compared with the previous system.

| Fan Power | 30 kW |

| Fan Airflow Range | 21,830–38,202 m³/h |

| Wind Pressure | 3314–2314 Pa |

| Fan Material | FRP |

| Motor / Electrical | 400V / 50Hz / 3P, explosion-proof electric machine |

| Control Cabinet | Controls the entire dust collector system; pulse blowing controlled by differential pressure; switchable. |

Start with the gas stream. The most important inputs are airflow rate, temperature, and humidity. These determine the required filter area, material selection, and whether condensation control is needed.

The inlet dust concentration (loading) drives the design margin. Higher loading typically requires a lower air-to-cloth ratio, stronger cleaning, and improved hopper/discharge handling to prevent re-entrainment and buildup.

Finer particles demand higher collection performance, while particle form affects dust cake behavior. Consider particle size distribution and shape (spherical vs fibrous) to avoid bleed-through, excessive blinding, or unstable pressure drop.

Define the target based on emission limits, indoor air requirements, and dust hazard level. Pulse-jet baghouses commonly achieve >99% collection efficiency when media, sealing, and cleaning are correctly matched to the process.

Select a cleaning regime—clean-on-time (fixed intervals) or clean-on-demand (triggered by differential pressure). Then set the air-to-cloth (A/C) ratio to balance stable ΔP, bag life, and energy use in continuous operation.

From design parameters (airflow, temperature, humidity, dust loading) to cleaning strategy and DP control, Omela supports your baghouse performance end-to-end.

Choosing the right filtration supplier affects everything from system stability to maintenance downtime. At Omela Filtration, we combine reliable materials, controlled production, and years of industry experience to support dust and liquid filtration needs across different plants and applications.

We use consistent-grade filter media, sewing thread and metals sourced from qualified suppliers. Each batch is checked for weight, thickness, air permeability and tensile strength to keep performance steady across shipments.

Our facility is equipped with modern sewing lines, hot-welding machines and automated inspection tools. This keeps production efficient and helps us meet tight delivery schedules, even on custom orders.

Our engineers and technicians have long experience with dust collectors, liquid systems and industry-specific conditions. They help you match materials to temperature, chemistry and air-to-cloth ratios to avoid unnecessary failures.

From sampling to documentation and shipping, our team responds quickly and keeps information clear. Customers in cement, asphalt, power and water-treatment plants rely on our service to resolve problems without delay.

From the first technical discussion to installation and long-term maintenance, our team stays involved at every stage. We analyze your operating conditions, adjust product designs when needed, and ensure the final filtration setup works reliably in real plant environments. After delivery, our service team continues to provide guidance and troubleshooting support, helping you keep your system stable and downtime low.

A pulse jet baghouse dust collector is a fabric filtration system that removes particulate matter from industrial exhaust gases using filter bags cleaned by short bursts of compressed air.

Pulse jet cleaning allows continuous operation at relatively higher air-to-cloth ratios compared to shaker or reverse-air baghouses.

Baghouse sizing is primarily based on the air-to-cloth (A/C) ratio, which defines the relationship between airflow rate and total filter media surface area.

Improper sizing often results in excessive pressure drop, unstable emissions, and short bag life.

There is no single universal air-to-cloth ratio. The appropriate value depends on multiple operating factors:

Selecting an incorrect A/C ratio is one of the most common causes of premature filter bag failure.

Airflow rate directly determines:

Excessive airflow leads to higher differential pressure, dust penetration, and accelerated media wear.

Temperature is a primary limiting factor when selecting filter media.

Media must withstand both continuous operating temperatures and short-term excursions without degradation.

High humidity can cause condensation inside the baghouse, resulting in:

In humid conditions, media selection, surface treatment, and temperature control become especially critical.

Dust loading affects:

Higher inlet dust loads require lower air-to-cloth ratios and more conservative cleaning strategies.

Fine particles are more difficult to capture and increase the risk of:

Fine or submicron dust often requires coated or membrane filter media.

Particle shape strongly influences dust release behavior:

Difficult dusts typically require surface-treated or membrane media to maintain cleanability.

Properly designed pulse jet baghouses routinely achieve collection efficiencies above 99%.

Actual efficiency depends on media selection, sealing quality, airflow distribution, and cleaning control.

Differential pressure represents the resistance to airflow across the filter media.

Stable DP reflects balanced airflow and effective cleaning.

Pulse jet baghouses use compressed air and typically operate under:

This method is especially effective for processes with variable operating conditions.

Most failures are design- or operation-related, not manufacturing defects.

Replacement frequency varies widely by application.

In severe continuous-duty systems, annual replacement rates may range from 25% to 50% of installed bags.

Yes, but additional design precautions are required, including:

Optimized design focuses on stable DP, efficient cleaning, and long bag life.

Yes. Many performance issues can be resolved through:

Retrofit solutions often deliver substantial performance improvements without full system replacement.

With 20+ years of experience and 1000+ global clients, we deliver stable filtration performance and dependable dust-collector operation.