Aluminum oxide filter bags are a type of high-temperature filter bag that is commonly used in industrial applications such as foundries, steel mills, and incinerators. These filter bags are designed to withstand extreme temperatures and harsh environments, making them an effective solution for capturing and containing dust and other airborne contaminants. This article will provide an overview of aluminum oxide filter bags, their benefits, and their applications.

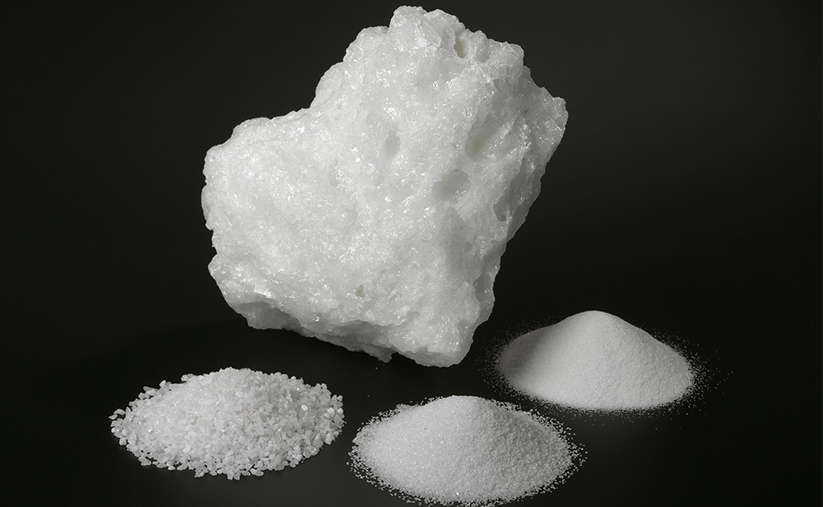

Aluminum oxide filter bags are made from a synthetic fiber material that is coated with aluminum oxide. This coating provides the filter bag with excellent thermal and chemical resistance, making it suitable for use in high-temperature and corrosive environments. Aluminum oxide filter bags can withstand temperatures of up to 500°C and are resistant to most chemicals, acids, and alkalis.

1. High-Temperature Resistance: Aluminum oxide filter bags can withstand high temperatures, making them suitable for use in applications where other filter bags would fail.

2. Chemical Resistance: The aluminum oxide coating on the filter bag provides excellent chemical resistance, making them suitable for use in corrosive environments.

3. Long Life: Aluminum oxide filter bags have a long life and can withstand harsh operating conditions, reducing the need for frequent replacements.

4. High Filtration Efficiency: Aluminum oxide filter bags have a high filtration efficiency, capturing even fine particles and contaminants.

Foundries: Foundries generate a significant amount of dust and other airborne contaminants. Aluminum oxide filter bags are an effective solution for capturing and containing these contaminants.

Steel Mills: Steel mills generate high temperatures and harsh environments that require durable and efficient filter bags. Aluminum oxide filter bags are an ideal solution for these applications.

Incinerators: Incinerators generate high temperatures and produce hazardous and toxic waste. Aluminum oxide filter bags are effective in capturing and containing these contaminants.

Aluminum oxide filter bags are an excellent solution for high-temperature and harsh environment applications. They offer excellent thermal and chemical resistance, long life, high filtration efficiency, and are cost-effective. By choosing aluminum oxide filter bags for their specific needs, operators can ensure the effectiveness of their dust collection systems and protect their workers’ health and safety.

| Types | Operating Temperature ℃/℉ | Instant Temperature℃/℉ | Abrasive Resistance | Hydrolytic Stability | Acid Resistance Alkali | Alkali Resistance | Oxidation Resistance |

| Polypropylene | 80/176 | 100/212 | Excellent | Good | Excellent | Excellent | Restricted |

| Homopolymer Acrylic | 140/284 | 160/320 | Good | Moderate | Excellent | Excellent | Good |

| Polyester | 130/266 | 150/302 | Excellent | Moderate | Moderate | Moderate | Good |

| PPS | 190/374 | 220/428 | Excellent | Moderate | Excellent | Moderate | Moderate |

| Nomex | 204/399 | 240/464 | Excellent | Good | Good | Good | Moderate |

| P84 | 260/500 | 280/536 | Excellent | Moderate | Excellent | Moderate | Good |

| PTFE | 250/482 | 300/572 | Good | Excellent | Excellent | Excellent | Excellent |

| Fiberglass | 240/464 | 280/536 | Good | Moderate | Good | Good | Restricted |

| FMS | 240/464 | 280/536 | Good | Moderate | Good | Good | Restricted |

Introduction Efficient particulate collection is central to modern industrial air pollution control, making the baghouse a familia

By Omela Filtration — Industrial Filtration Experts 1. Industry Background and the Real Problem In pulse-jet dust collector syst

By Omela Filtration – Industrial Filtration Experts Industry Background and Challenges Most industrial dust collector systems re