Proper installation of polypropylene filter bags is crucial for ensuring optimal filtration performance and longevity in various industrial applications, including the pharmaceutical industry. This article provides a detailed installation manual, including a diagram and a parameters table to guide the process.

| Parameter | Polypropylene Filter Bags |

|---|---|

| Temperature Limit | Up to 90°C (194°F) |

| Chemical Resistance | Excellent |

| Abrasion Resistance | Moderate |

| Filtration Efficiency | High |

| Installation Time | Approximately 30 minutes |

| Tools Required | Wrench, gloves, safety goggles |

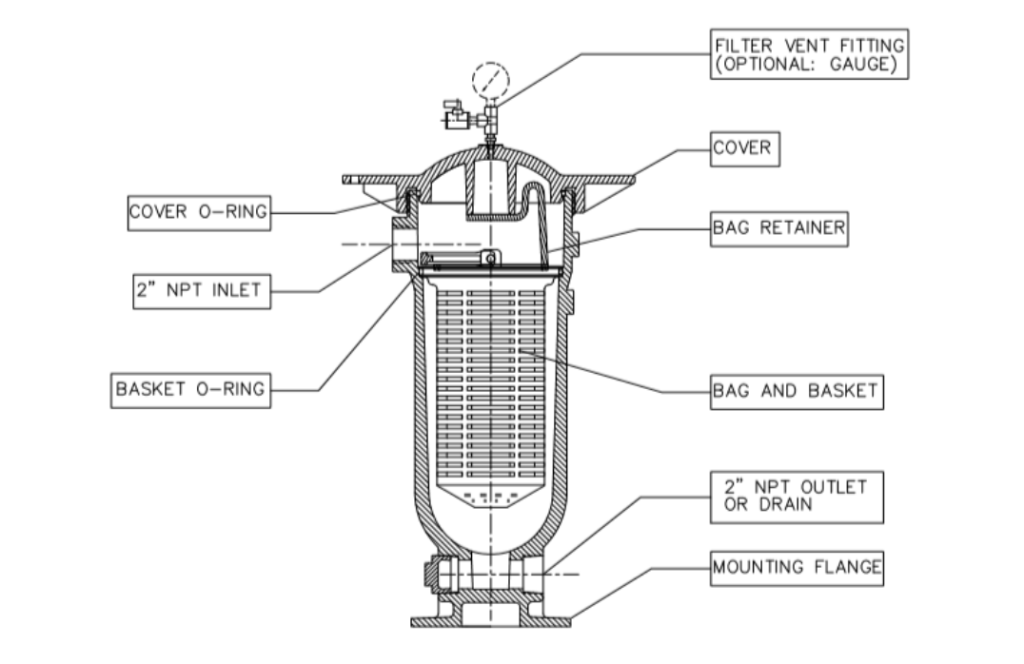

Below is a simplified diagram of the installation process for polypropylene filter bags:

+-------------------------------+

| Filter Housing |

| +----------------+ |

| | | |

| | Filter Bag | |

| | | |

| +----------------+ |

| | | |

| | | |

| Seal/Gasket | |

| | |

| +------------+-----------+

| | |

| | Support Basket |

| | |

+------+------------------------+Proper installation of polypropylene filter bags is essential for maintaining efficient and effective filtration in industrial applications. By following the steps outlined in this manual and using the provided parameters table and diagram, you can ensure a secure and reliable installation. This process will help in achieving optimal performance and longevity of your filtration system.

Our products and services extend globally, including the following countries:

Introduction Efficient particulate collection is central to modern industrial air pollution control, making the baghouse a familia

By Omela Filtration — Industrial Filtration Experts 1. Industry Background and the Real Problem In pulse-jet dust collector syst

By Omela Filtration – Industrial Filtration Experts Industry Background and Challenges Most industrial dust collector systems re