In thermal power plants utilizing pulverized coal gasification, maintaining efficient and effective filtration is crucial for both operational efficiency and environmental compliance. The selection of appropriate filter bags plays a vital role in capturing fine particulate matter and ensuring smooth operations. This article outlines the recommended types of filter bags, their parameters, and maintenance practices for optimal performance.

For pulverized coal gasification in thermal power plants, the following filter bag materials are recommended due to their specific properties and suitability for high-temperature and abrasive environments:

| Parameter | Nomex (Aramid) | P84 | PTFE-Coated |

|---|---|---|---|

| Temperature Limit | Up to 200°C (392°F) | Up to 260°C (500°F) | Up to 250°C (482°F) |

| Chemical Resistance | Moderate | High | Very High |

| Abrasion Resistance | High | Moderate | High |

| Application | High-temperature zones | High-temp. and chemical environments | Aggressive gas streams |

Our products and services extend to numerous countries, ensuring we meet diverse industrial needs worldwide. We cover the following countries:

Selecting the right filter bags for pulverized coal gasification in thermal power plants is essential for maintaining efficient operations and compliance with environmental regulations. Nomex, P84, and PTFE-coated filter bags offer excellent performance in high-temperature and chemically aggressive environments, ensuring the longevity and efficiency of the filtration system.

Understanding the Risk: Dust Explosion Fundamentals Dust explosions represent one of the most serious safety hazards in industrial

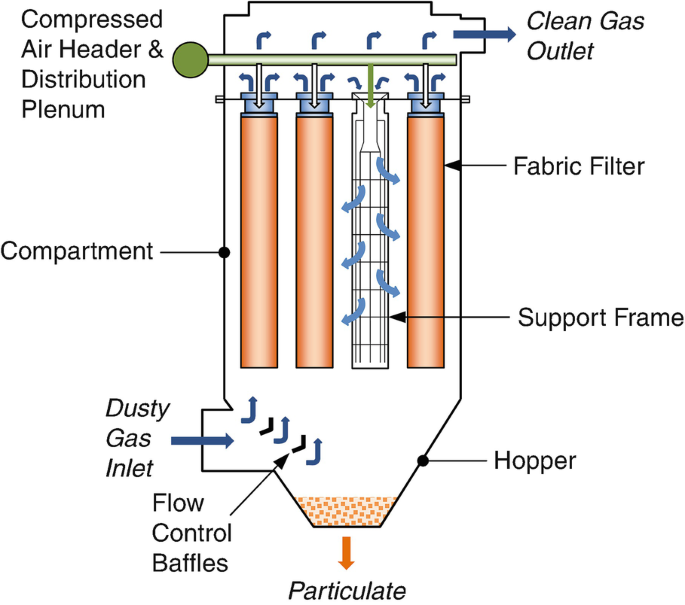

Introduction Efficient particulate collection is central to modern industrial air pollution control, making the baghouse a familia

By Omela Filtration — Industrial Filtration Experts 1. Industry Background and the Real Problem In pulse-jet dust collector syst